Crushing Sale Approach For Fine Grinding

Fine grinding: How mill type affects particle shape characteristics

2017年9月1日 Energy efficiency is probably the most significant advantage of stirred mills over traditionally used tumbling mills for fine grinding, and is likely to remain one of the dominant 2024年3月1日 Propose a multistep grinding process optimization method for hard brittle materials with variable grinding depth Prove the effectiveness of the optimization method and Optimization of grinding process for hard and brittle 2017年3月4日 Crushing and grinding are the two primary comminution processes Grinding equipments are used in the mineral s mining industry (PDF) SIZE REDUCTION BY GRINDING METHODS sbm crushing sale approach for fine g Find file Blame History Permalink lab 09ddb561 chengxinjia authored Nov 03, 2022 09ddb561 Historysbm crushing sale approach for fine grindingmd GitLab2024年6月5日 Simply stated, the role of the mill in fertilizer processing is to crush/grind/pulverise the raw phosphate rock Typically, the aim is to reduce quarter inchsize The importance of phosphate milling Bradley PulverizerFine grinding is the stage of comminution following secondary crushing, and reduces feed of 0625 to 0312 cm (025 to 0125 in) in size down to fine powderFine Grinding SpringerLink

.jpg)

Ultrafine Grinding an overview ScienceDirect Topics

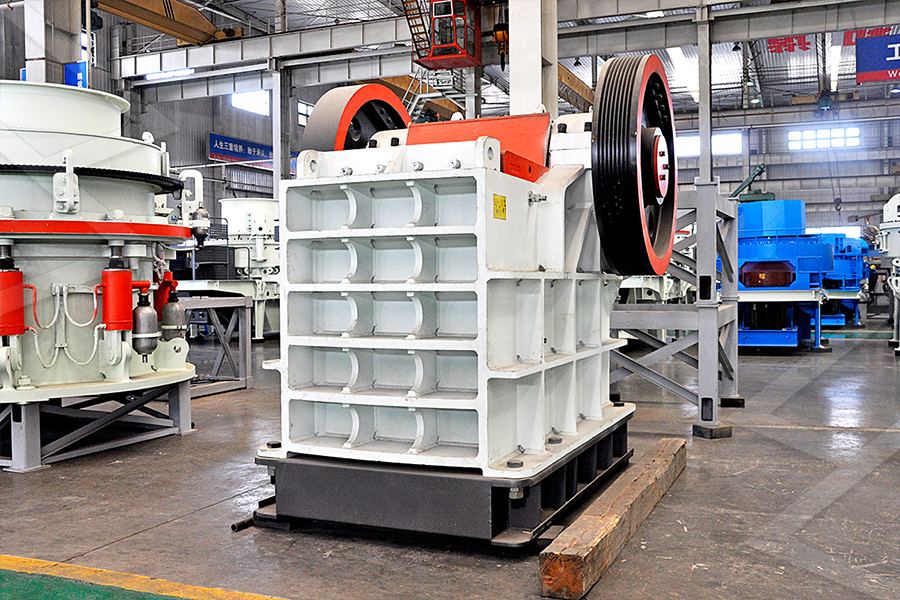

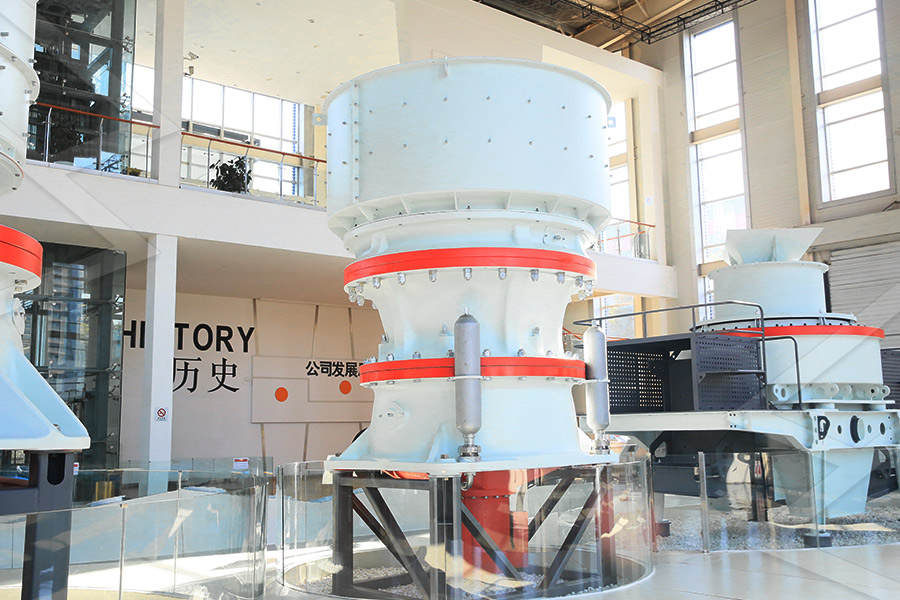

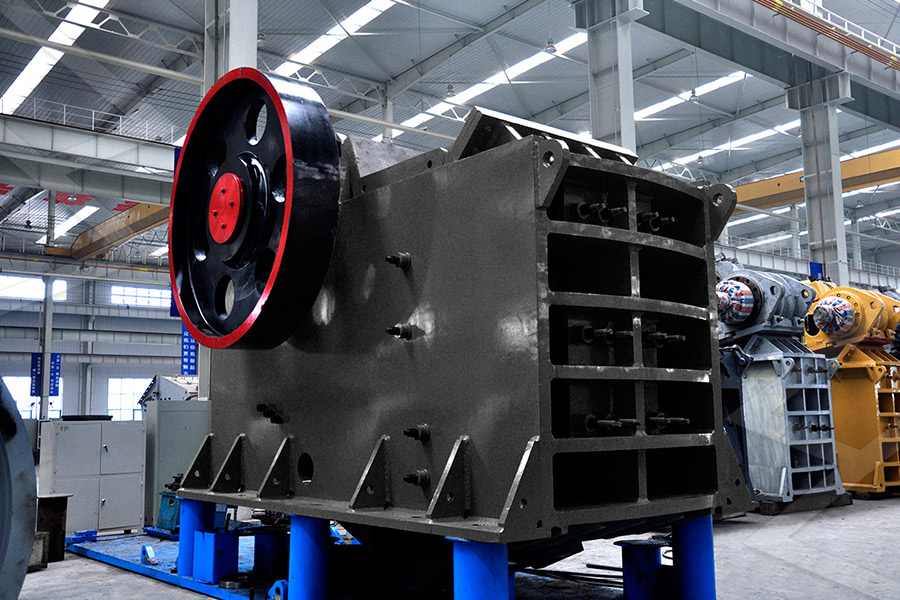

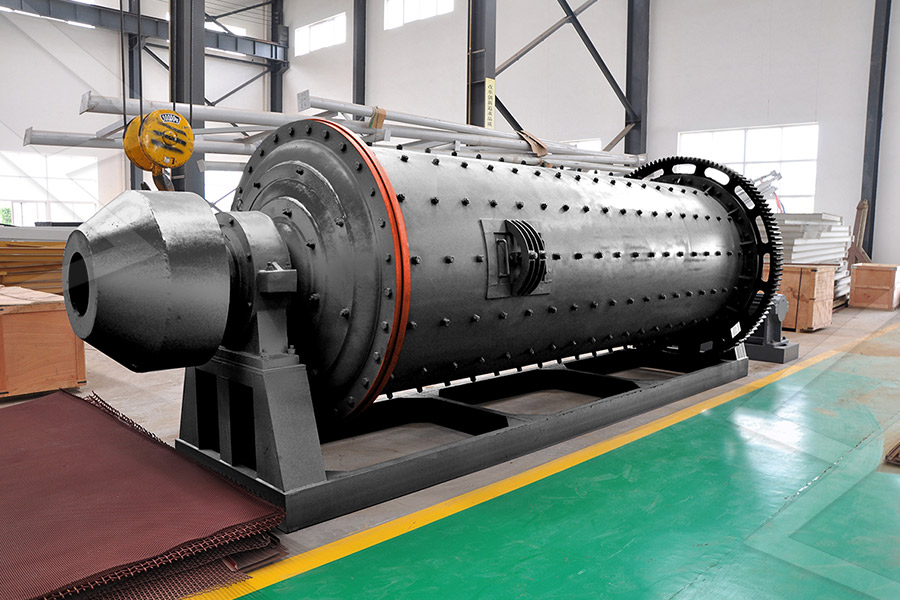

This involves several crushing stages, followed by grinding stages These crushing stages usually involve several unit operations in series, such as jaw crushers, cone crushers, hammer mills, 2021年5月14日 Finer grinding usually takes place in rotating vessels, such as ball and rod mills Very fine grinding, to sizes less than 10 μm, requires high energy and attrition mills are often 11 Crushing and classification particlesukThe ideas are applicable to the grinding of all brittle raw materials or semi finished industrial products The special problems of cement grinding and thm;e of hall mills are explained in more detail; in cement grinding we have to meet special The Process of Fine Grinding SpringerLink2021年7月31日 Simply stated, the role of the mill in fertilizer processing is to crush/grind/pulverise the raw phosphate rock Typically, the aim is to reduce quarter inchsize The importance of phosphate milling BC InsightThe final stage of crushing is increasingly carried out using high pressure grinding rolls (HPGRs), which involve the relatively efficient process of the slow compression of a particle bed, and can produce a fine feed for the grinding circuit [3], in some cases even making the coarser grinding stages redundant [4, 5]Ultrafine Grinding an overview ScienceDirect TopicsWilliams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer Rock Crushers Pulverizers Williams Crusher

.jpg)

刨(planing)、铣(milling)、磨(grinding)等加工一金属平面

2013年1月21日 这个其实这样的,刨一般用于加工余量多的粗加工,工件表面的 粗糙度 高,效率最高;铣(可以单不限于表面)工艺加工表面,算是 半精加工,可以去除大的工件余量,效率也很高,工具主要是 面铣刀,进度能控制在002,技术好的话;磨,则是完全精加工了,一般是铣完之后,或者是热处理之后 2004年12月10日 Whereas the state of the art of fine grinding technology for brittle materials is very high, thermoplastic, elastic, or fibrous materials cannot yet be ground as efficiently as brittle materials This effect is the main reason that the material is not grindable at ambient temperature with impact crushing At ambient temperatures, the Optimised technologies for cryogenic grinding ScienceDirect2022年3月15日 Replacing traditional primary grinding equipment with highpressure grinding rolls (HPGR) consists of another energysaving approach (NapierMunn, 2015) Therefore, improving the process control of an HPGR circuit may enable further reductions, but studying this solution requires simulation modelsUnifying highpressure grinding rolls models ScienceDirectThe Laboratory Disc Pulverizer Pulverisette 13 Premium Line is designed for batch or continuous fine grinding of hardbrittle to mediumhard solids, down to 50µm Quantity Add to Quote request This Laboratory Jaw Crusher is designed for fast and effective precrushing of very hard, hard, mediumhard, and brittle materials, even ferrous Crushers, Pulverizers, Grinders Lavallab2010年1月1日 Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing and stirred milling for fine grinding, has (PDF) Reducing Grinding Energy and Cost Magnetite Iron2021年6月11日 For example, if the sample surface had several raised areas, plane grinding would flatten those areas to a similar condition as the rest of the surface The second step in the grinding process is known as fine grinding The goal of fine grinding is to reduce damage and surface roughness of samples to a degree that is suitable for polishingSample Preparation – Grinding and polishing explained

Roll Crushers 911Metallurgist

Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward Rolls crush by 1996年1月1日 Localized plastic deformation, which should be more significant for the silicon nitride, would reduce the stress intensity and crushing depth 3 Machining Approach The machining approach to investigating grinding mechanisms typically involves measurement of cutting forces coupled with microscopic observations of grinding debris and surface Grinding Mechanisms for Ceramics ScienceDirectFrom precrushers for the comminution of coarse materials to jet and ball mills for ultrafine grinding: Hosokawa Alpine offers mills for a wide range of fineness levels Precrusher are used for coarse crushing and break up coarse Grinding Hosokawa Alpine2019年1月1日 The buhrstone mill, shown in Fig 518, is one of the oldest forms of fine crushing equipment, though it has been very largely superseded now by roller mills Grinding takes place between two heavy horizontal wheels, one of which is stationary, and the other is drivenParticle Size Reduction and Enlargement ScienceDirect2010年8月1日 Traditionally, for minerals, applications have included pregrinding or regrinding in iron ore pellet feed preparation circuits, or as secondary or recrushing devices in Kimberlite processing In the latter case, the unit was introduced in the recrushing of DMS product, but effectively operated as open circuit unit ( Maxton et al, 2002 )Flowsheet considerations for optimal use of high pressure grinding 2021年11月25日 Fine crushing in ballmills Transactions of the American Institute of Mining Engineers 61, 250296 Hukki, RT, Allenius, H, 1968 A quantitative investigation of the closed grinding circuit Society of Mining Engineers, AIME, Transactions 241, 482488 Schönert, K, 1988 A first survey of grinding with highcompression roller millsQuantifying the energy efficiency of fine grinding circuits

Optimization of grinding process for hard and brittle

2024年3月1日 The machining amount (200 μm and 50 μm for semifine grinding and fine grinding) is far more than the damage depth (4675 μm, 1667 μm) produced by the previous process Similar processing methods were also discussed in the work of Wang et al [36] The purpose is to eliminate the impact of damage caused by the previous process2020年9月7日 There are also several grinding mill machine: Raymond mill, High pressure grinding mill, and Micro powder grinding mill etc However, in most case, a small crusher is needed in the grinding mill machine The crusher is used for crushing the raw material into smaller size, which is more convenient to grinding into super fine sizeWhat is the difference between crushing and grinding?fine crushed calcite – Newest Crusher, Grinding Mill, Mobile The stone crusher machine for crushing calcite, calcite powder Heavy calcium fine powder for artificial stone, and artificial floor tiles, and natural rubber, and Crushed Rock Fine Powder Grinding MachineRock Crushing Equipment for Sale jaw crusher Capacity: 11120t/h Feed Size: 1001200mm Output Size: 10350mm impact crusher Eastmancrushing understands crushing and grinding machines well We are one of the leaders in rock crushing in China for about 40 years Fine crushing In this crushing stage, the quality and quantity of fine Rock Crusher Eastman Rock Crusher2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment investment in crushing operations accounts for 65% to 70% of the total plant value, power consumption is about 50% to 65%, and steel consumption is as Crushing and Grinding Process JXSC Machine2017年9月1日 After fine grinding, the chromite had very similar shape characteristics to the silicates, although significant differences were observed between the progeny of the two mill types (Little et al, 2015) This paper aims to explore these observations further, focusing on the two fine grinding devices and the breakage mechanisms therein, size by Fine grinding: How mill type affects particle shape characteristics and

.jpg)

Grinding Mills and Their Types IspatGuru

2015年4月9日 Very fine grinding mills The following are the mills used for very fine grinding Hammer mills Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm A set of ‘hammers’ rotate about a Manure grinder is a machine for crushing manure materials into powders Why should you buy fine powder grinder for your fertilizer production line? Manure grinder for sale Model: SXFLF600 Power: 22kw Capacity: 35t/h Size of Manure Grinder Fine Powder Making Features 2007年1月24日 磨削加工中,grinding,lapping,polishing的字面上的翻译都是“研磨”,但实际上他们好像的精密磨削加工的三个不同的步骤?具体是怎么区别的呢? 磨削加工中,grinding, lapping, polishing的字面上的翻译都是“研磨”,但实际上他们好像的精密磨削加工的三个不同的步骤?磨削加工中grinding, lapping, polishing 有什么区别? 百度知道China LIMING Heavy Industry Science and Technology Co LTD which mainly manufacture large and mediumsized crushing and grinding equipments was founded in 1987 Fine grinding, low carbon and environmental protection READ MORE 04 LIMING's salesnet, covering over 170 countries and regions from different continents and overseas offices Stone Crushers, Mill and Grinding2017年8月25日 Generally the objective of crushing is to accomplish size reduction, and occasional ly the additional requirement to generate a minimum amount of fine particles is imposed One distinction between crushing and grinding equipment is that the working surfaces of crushing equipment do not make contact with each other during size reductionCHAPTER 5 GENERAL PRINCIPLES OF MINERAL 2013年12月31日 These days advanced fine and ultrafine grinding technology adaptation becomes increasingly common in mineral processing plants to liberate the valuable minerals from finegrained and lean grade A developed approach based on grinding time to determine

.jpg)

Pulverizer Machine Manufacturer, Supplier Pulverizer india

3 天之前 A highly genuine and elegant name of the nation engrossed in the leading Manufacturer, exporter, supplier, Pulverizer Machine in IndiaWe provide highquality machines all over India A pulverizer is also known as Grinder in simple termsThe unit is provided with a provision for affixing mesh of various sizes as per requirement and nature of the material to be 2004年12月10日 The theory of grinding has mainly been developed in the mineral industry as a response to needs for maximising production capacity and minimising energy use for low value added products (Prasher, 1987)On one hand, literature gives many examples of experimental investigations with different types of mill and numerous types of mineral powders for validating Comparison of various milling technologies for grinding pharmaceutical 2023年9月13日 The coarsegrained materials then enter the ultrafine grinder for crushing When the feed contains a large amount of qualified ultrafine powder, using this process can reduce the load on the crusher, reduce energy consumption per unit of ultrafine powder product, and improve operating efficiency7 basic process flows of ultrafine grinding ALPA Powder4 天之前 Crushing and grinding are two processes used in manufacturing and natural sciences These processes are used to produce many different products 10 In fine grinding, the feed size is 5 2 mm, and the product size is 01 mm (about 200 mash) 11 Energy consumption per unit mass of product is high due to fine particle productionDifference Between Crushing and Grinding OperationsThe final stage of crushing is increasingly carried out using high pressure grinding rolls (HPGRs), which involve the relatively efficient process of the slow compression of a particle bed, and can produce a fine feed for the grinding circuit [3], in some cases even making the coarser grinding stages redundant [4, 5]Ultrafine Grinding an overview ScienceDirect TopicsWilliams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer Rock Crushers Pulverizers Williams Crusher

刨(planing)、铣(milling)、磨(grinding)等加工一金属平面

2013年1月21日 这个其实这样的,刨一般用于加工余量多的粗加工,工件表面的 粗糙度 高,效率最高;铣(可以单不限于表面)工艺加工表面,算是 半精加工,可以去除大的工件余量,效率也很高,工具主要是 面铣刀,进度能控制在002,技术好的话;磨,则是完全精加工了,一般是铣完之后,或者是热处理之后 2004年12月10日 Whereas the state of the art of fine grinding technology for brittle materials is very high, thermoplastic, elastic, or fibrous materials cannot yet be ground as efficiently as brittle materials This effect is the main reason that the material is not grindable at ambient temperature with impact crushing At ambient temperatures, the Optimised technologies for cryogenic grinding ScienceDirect2022年3月15日 Replacing traditional primary grinding equipment with highpressure grinding rolls (HPGR) consists of another energysaving approach (NapierMunn, 2015) Therefore, improving the process control of an HPGR circuit may enable further reductions, but studying this solution requires simulation modelsUnifying highpressure grinding rolls models ScienceDirectThe Laboratory Disc Pulverizer Pulverisette 13 Premium Line is designed for batch or continuous fine grinding of hardbrittle to mediumhard solids, down to 50µm Quantity Add to Quote request This Laboratory Jaw Crusher is designed for fast and effective precrushing of very hard, hard, mediumhard, and brittle materials, even ferrous Crushers, Pulverizers, Grinders Lavallab2010年1月1日 Application of more efficient grinding technologies developed in the last 20 years, including high pressure grinding rolls (HPGR) for fine crushing and stirred milling for fine grinding, has (PDF) Reducing Grinding Energy and Cost Magnetite Iron2021年6月11日 For example, if the sample surface had several raised areas, plane grinding would flatten those areas to a similar condition as the rest of the surface The second step in the grinding process is known as fine grinding The goal of fine grinding is to reduce damage and surface roughness of samples to a degree that is suitable for polishingSample Preparation – Grinding and polishing explained

Roll Crushers 911Metallurgist

Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward Rolls crush by 1996年1月1日 Localized plastic deformation, which should be more significant for the silicon nitride, would reduce the stress intensity and crushing depth 3 Machining Approach The machining approach to investigating grinding mechanisms typically involves measurement of cutting forces coupled with microscopic observations of grinding debris and surface Grinding Mechanisms for Ceramics ScienceDirect