Designing Crushing Plants

.jpg)

Crushing Plant Design and Layout Considerations 911

2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a crushing and screening is a most fruitful area for achieving economies in overall Scientific Methods to DesiDesigning a crushing plant involves various steps and considerations to ensure high efficiency, safety, and costeffectiveness Here’s a general guide to help you design a crushing plant: 1 How to design a crushing plant zenithmineral2024年9月24日 crushing and screening is a most fruitful area for achieving economies in overall mill performance In order to realize how gains can be made, it is necessaryScientific Methods to Design Crushing and Screening 2016年2月10日 This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour There are three main steps in designing a Design of a crushing system that improves the crushing There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, Crushing Plant Design: Layout Considerations

.jpg)

Stone, mineral crushing plant design and layout

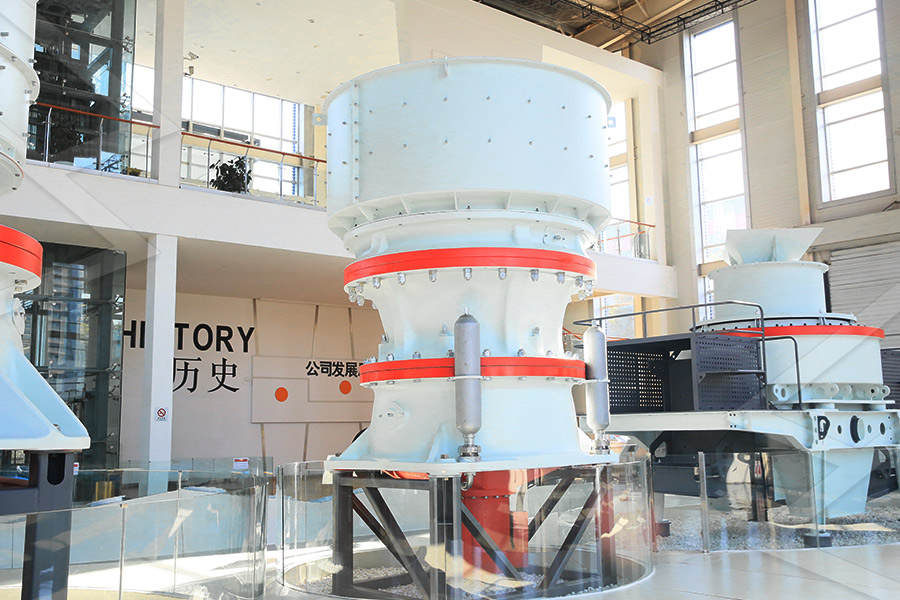

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum A welldesigned plant layout Crushing Plant Design and Layout Yeco In the world of bulk material treatment facilities, the design and engineering of crushing plants play a critical role in ensuring efficient and effective operations Crushing plants are essential Little PEng Engineering for Crushing Plants Design in Bulk 2016年3月11日 The majority of crushing plants recently constructed have accomplished this desired efficiency by optimizing plant design, crusher design and automation By improved efficiency a decrease in energy consumption Crushing Plant Flowsheet DesignLayout2023年2月23日 This comprehensive guide provides valuable insights into the design and construction of an efficient aggregate crushing plant From selecting the right equipment to The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant2023年2月24日 Factors to Consider When Designing a 200 TPH Stone Crushing Plant Designing a stone crushing plant is a complex process that requires careful consideration of several factors Some of the factors that need Comprehensive Guide to Designing a 200 TPH

.jpg)

Crushing and Screening Handbook AusIMM

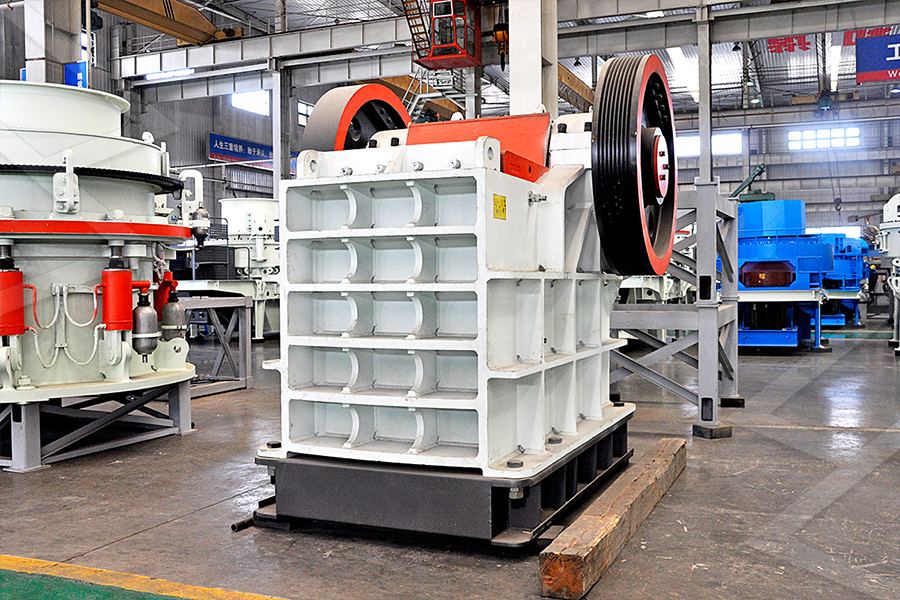

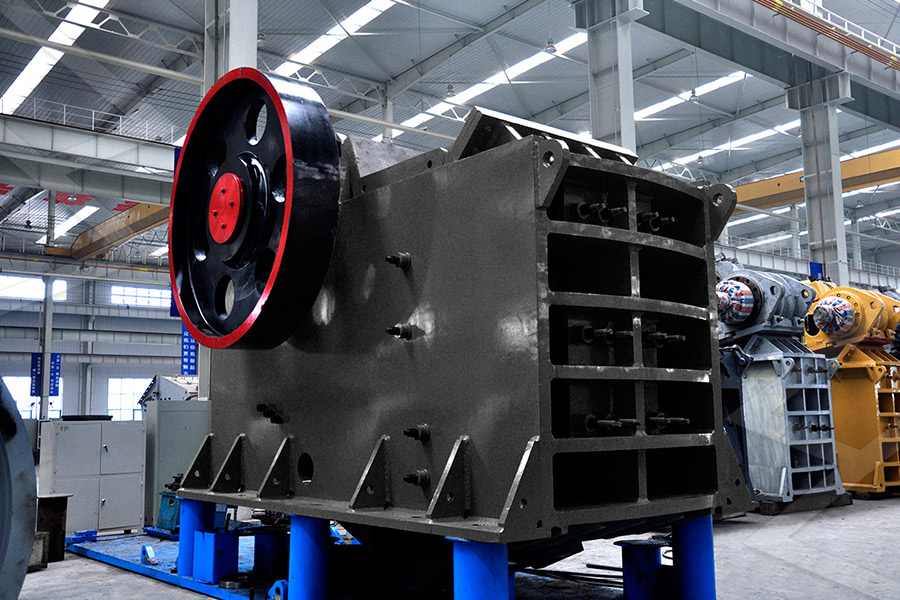

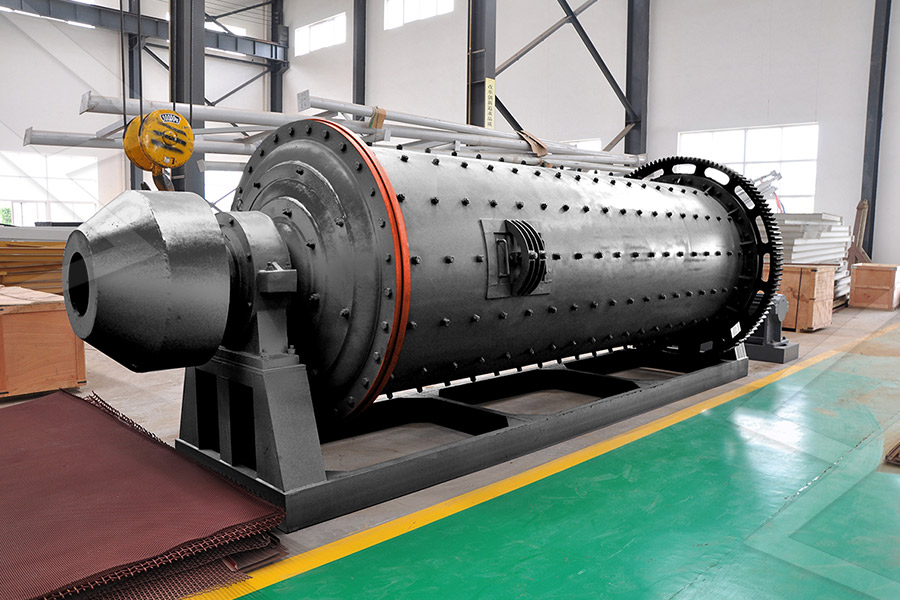

2021年6月24日 When designing a new plant, we balance raw material characteristics with the required production rate and the size and shape of the fi n Trackmounted crushing plants – fully mobile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge conveyors Easily2020年10月27日 Designing a Crushing Screening Plant – Part I Primary Jaw Crushing Stage 20201027 Introduction The jaw crusher is the first stage in the crushing and screening process, the main purpose of this stage is to crush the Designing a Crushing Screening Plant – Part I2018年1月19日 Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital There are three main steps in designing a good crushing plant: process design, equipment selection, andMineral Processing Plant Design University of 2023年12月24日 other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations MINE 2012年10月15日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, preexisting factors may overrule the ability to incorporate some or all of these considerations It is not intended to recommend specific Enhanced Plant Design for Aggregate Processing AggNet2013年2月1日 Saving money while designing new plants The widest possible benefits from the Bruno simulation software can be achieved when designing a new crushing and screening plant or a mining process Any test run for a stationary or mobile process may be quite expensive and time consumingRock processing simulation software Engineer Live

.jpg)

Enhanced plant design for aggregate processing Quarry

2012年1月5日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, preexisting factors may overrule the ability to incorporate some or all of these considerations It is not intended to recommend specific types or brands of machines 2010年8月18日 In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated New Trend in Crushing Plant Design and Layout Considerationsmethod described in the paper can be a useful tool when designing crushing plants or when optimizing the output of compressing crusher Machines Contributor(s): C M Evertsson Return to parent product Prediction of Size Distributions from Compressing Crusher Machines Prediction of Size Distributions from Compressing Crusher Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance My Plant Planner is packed full of unique features and insights to help you plan your crushing and My Plant Planner MetsoThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesdesigning crushing plants pububossa1995年1月1日 The method described in the paper can be a useful tool when designing crushing plants or when optimizing the output of compressing crusher Machines During the last few years the quality requirements on roads and railroads have become more accentuated due to the desire to minimise maintenance costs This has, in turn, led to increasing OneMine Prediction of Size Distributions from Compressing

(PDF) Crushing and Screening Handbook Academia

Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Since the crushing plants operate under harsh conditions and involve very abrasive material, multiple factors can influence their performance This paper assesses a number of factors affecting the 2014年8月21日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of parties These can include the owner’s engineering staff Setting up of crushing plant: design and layout considerationsBaioni Crushing Plants – Crushing and Water Treatment Plants Mobile crushing screening plants We design and manufacture modular system, portable solutions on tracks to be used in the primary, secondary, tertiary crushing of aggregates, in their screening and storage stages, whether they are materials from quarries, mines or recycling of construction waste and Designing Crushing Plants ouestsalonhabitatWe manufacture about 1520 machines per month of various capacities specifications using advanced and automatic machines Our core specialization lies in designing crushing plant layouts according to customer’s requirement and we recommend machines and equipment to suit the customer’s requirement efficiently and economicallyRD SPECIAL ALLOY STEEL Stone Crusher Manufacturer, For 2024年7月26日 other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911 2016年2月10日 up This paper addresses the critical design parameters that will increase the crushing capacity of the plant to 35 tonnes per hour There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The paper analyses all of these steps Keywords Gold mining, crushing, Zimbabwe, jaw crusher, cone Design of a crushing system that improves the crushing

.jpg)

CRUSHING SCREENING Crushing and Screening

2017年5月30日 designing our products based on a needs analysis, often identifying vital factors that even the client wasn’t aware of This is the reason why Meka crushing and screening plants and concrete plants are preferred in regions with widely varying environmental and geographical conditions, such as England, Ecuador, Siberia, Chile, the Comoro Islands,2023年2月24日 Factors to Consider When Designing a 200 TPH Stone Crushing Plant Designing a stone crushing plant is a complex process that requires careful consideration of several factors Some of the factors that need Comprehensive Guide to Designing a 200 TPH 2021年6月24日 When designing a new plant, we balance raw material characteristics with the required production rate and the size and shape of the fi n Trackmounted crushing plants – fully mobile jaw, cone or impact crushing plants, with or without screens, and equipped with open or closed circuit and discharge conveyors EasilyCrushing and Screening Handbook AusIMM2020年10月27日 Designing a Crushing Screening Plant – Part I Primary Jaw Crushing Stage 20201027 Introduction The jaw crusher is the first stage in the crushing and screening process, the main purpose of this stage is to crush the Designing a Crushing Screening Plant – Part I2018年1月19日 Crushing Plant Design and Layout Considerations Introduction In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital There are three main steps in designing a good crushing plant: process design, equipment selection, andMineral Processing Plant Design University of 2023年12月24日 other words, crushing plants, from primary to quaternary circuits, are here to stay There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations MINE

Enhanced Plant Design for Aggregate Processing AggNet

2012年10月15日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, preexisting factors may overrule the ability to incorporate some or all of these considerations It is not intended to recommend specific 2013年2月1日 Saving money while designing new plants The widest possible benefits from the Bruno simulation software can be achieved when designing a new crushing and screening plant or a mining process Any test run for a stationary or mobile process may be quite expensive and time consumingRock processing simulation software Engineer Live2012年1月5日 The intention of this article is to provide an overview of matters to be considered when designing a crushing and screening plant, starting with a blank sheet – when planning a plant upgrade or extension, preexisting factors may overrule the ability to incorporate some or all of these considerations It is not intended to recommend specific types or brands of machines Enhanced plant design for aggregate processing Quarry2010年8月18日 In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimum There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated New Trend in Crushing Plant Design and Layout Considerationsmethod described in the paper can be a useful tool when designing crushing plants or when optimizing the output of compressing crusher Machines Contributor(s): C M Evertsson Return to parent product Prediction of Size Distributions from Compressing Crusher Machines Prediction of Size Distributions from Compressing Crusher